Choosing a wire mesh weaving machine is crucial for businesses in various sectors. The wire mesh industry has shown steady growth, with a projected increase of 5.3% annually until 2027 (Smith Market Research). This demand highlights the importance of selecting the right machinery.

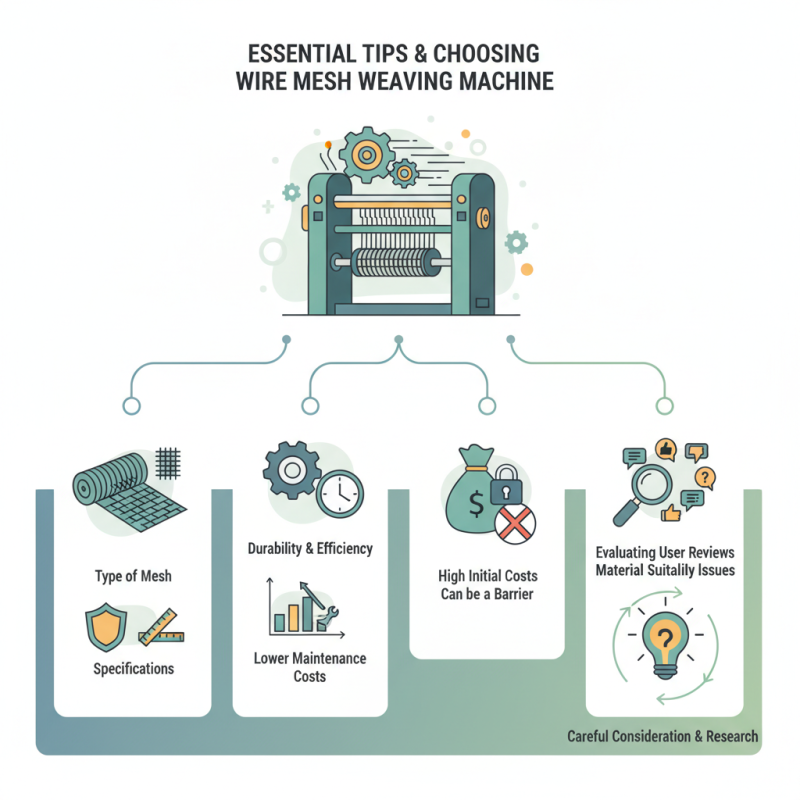

When selecting a wire mesh weaving machine, consider the type of mesh required. Different applications need different specifications. Durability and efficiency are also key factors. Machines that last longer mean lower maintenance costs. However, it’s important to remember that high initial costs can be a barrier.

The market offers numerous options, but not all machines meet quality standards. Some may fall short on performance or material suitability. Evaluating user reviews can uncover these issues. Users often report dissatisfaction with certain models. Making the right choice requires careful consideration and research.

When selecting a wire mesh weaving machine, understanding the types available is crucial for your needs. Various machines cater to different wire types, mesh sizes, and production rates. For instance, Jacquard weaving machines are ideal for complex patterns, while plain weaving machines serve basic mesh production. According to a recent industry report, the demand for automated weaving machines has increased by over 30% in the past five years due to rising efficiency needs.

Look for versatility in your choice. Machines that can handle various wire gauges and mesh sizes are a smart investment. If you often change production types, consider a modular system. This flexibility can reduce downtime and improve overall production efficiency. Even minor adjustments can yield significant improvements.

Additionally, always assess the maintenance requirements of your chosen machine. Some models may require frequent servicing, which could disrupt your workflow. Regular maintenance leads to longevity, but the initial learning curve can be challenging. This is an area where managers often overlook key details. Being prepared for troubleshooting could save you time and resources in the long run. Always research the experiences of other users to guide your decision.

Choosing a wire mesh weaving machine requires careful consideration of several key features. The type of mesh you plan to produce is crucial. Different machines are designed for specific mesh patterns and materials. Ensure the machine can handle the wire thickness you intend to use. It's important to note that not all machines perform well with thicker or thinner wires.

Automation is another feature to evaluate. Automatic machines can significantly increase production efficiency. However, they may require greater initial investment and maintenance. Manual machines offer flexibility but can slow down production. Consider your production needs carefully.

Additionally, ease of use is vital. A complicated interface can lead to operational errors. Look for machines with intuitive controls. Don’t overlook customer support either. It’s essential to have access to technical assistance when issues arise. Selecting a machine involves weighing these factors against your budget and objectives. Keep in mind that every choice has its trade-offs.

When selecting a wire mesh weaving machine, assessing production capacity and speed is crucial. A machine that fits your production needs will ensure efficiency. Think about how much output is required daily. High-speed machines can yield more but may also have a higher entry cost. Balancing these factors is essential for effective budgeting.

Understand the speed ratings of various models. Some machines weave faster but may compromise on quality. Look for machines that offer flexibility. This can help you adapt to varying production demands. Testing different speeds can also reveal unexpected challenges. Sometimes, slower speeds might produce better products.

Consider the materials you will be working with. Heavier materials might need more robust machines, while finer meshes can be produced with less power. Don’t overlook maintenance needs too. A machine that requires constant attention can hinder production flow. Weigh both speed and quality to make an informed choice.

| Machine Type | Production Capacity (kg/hour) | Max Speed (m/min) | Wire Diameter Range (mm) | Application Area |

|---|---|---|---|---|

| Automatic Weaving Machine | 300 | 50 | 0.5 - 3.0 | Industrial, Construction |

| Semi-Automatic Weaving Machine | 200 | 40 | 0.8 - 2.5 | Fencing, Agriculture |

| Manual Weaving Machine | 100 | 20 | 1.0 - 3.5 | Craft, Hobby |

| High-Speed Weaving Machine | 500 | 70 | 0.3 - 2.0 | Production Lines |

When it comes to selecting a wire mesh weaving machine, material compatibility is crucial. Different applications require specific types of wire and mesh. Understanding the materials you will be working with helps narrow down your options. If you plan to weave stainless steel, for example, ensure the machine can handle that material. Conversely, softer materials like aluminum require different mechanisms. Proper assessment guarantees durability and product performance.

Quality standards are key in ensuring the end product meets industry requirements. Machines should be able to produce consistent and high-quality mesh. Look for certifications or quality control measures in place. Ensure the machine aligns with your specific industry standards for safety and reliability. Not all machines will meet these standards, so a thorough investigation is necessary.

Tips: Always check the machine specifications carefully. Ask about the machine's capabilities with various materials. It's a good idea to request samples of the mesh produced by the equipment. This allows you to evaluate the quality firsthand. Sometimes, there are limitations that may not be advertised, so being proactive is vital. A good fit between the machine and materials makes a huge difference in production efficiency.

When selecting a wire mesh weaving machine, the supplier's reputation is crucial. Look for suppliers with a history of reliability. Reading customer reviews can provide insights. A good reputation often indicates quality products and dependable service. Users frequently share experiences that are informative. Online platforms are valuable for this research.

Service support options is another key factor. Immediate assistance can save frustration and time. Check if the supplier offers on-site support or remote troubleshooting. Some suppliers may have a dedicated service team, while others might rely on third-party providers. This difference can affect your choice. Quick response times are essential.

Evaluate the communication style of the supplier. Are they approachable and willing to answer your queries? Effective communication can reflect the potential for long-term partnership. Many may overlook this aspect, focusing only on the machine's specifications. However, building a strong relationship can lead to better support in the long run.

© 2025 RWC. All Rights Reserved. | Privacy Policy | Contractor’s License Number: 13VH00710200 | Sitemap | Areas Served